- Introduction

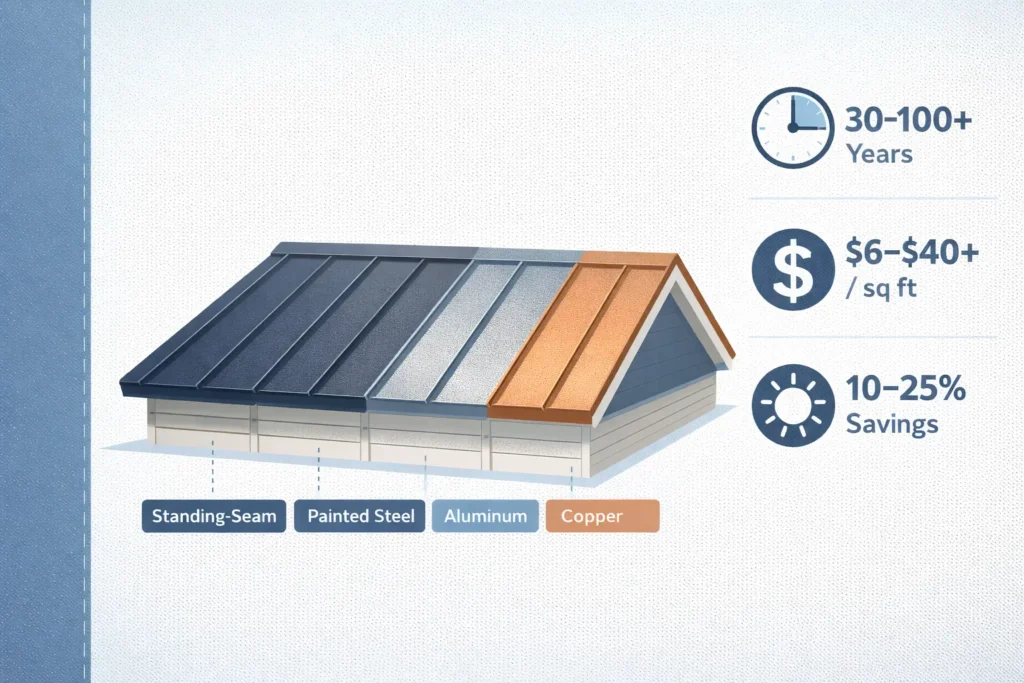

- Quick snapshot — what you need to know first

- How metal roof pricing works — basics explained

- Cost by material

- Cost by roof size

- Practical cost breakdown — exact line items

- Why standing seam costs more

- Energy and lifecycle savings — numbers that matter

- Real examples — calculate your expected total

- Factors that push the price up — checklist to watch

- Warranties and expected maintenance

- Choosing the right metal for your situation — short guide

- How to get accurate quotes — a simple process

- Financing and cost-saving strategies

- Long-term value: is metal worth it?

- Common contractor pricing traps to avoid

- Maintenance checklist

- Case study — sample budget and savings

- People Also Ask

- Final checklist before you sign a contract

- Conclusion

Introduction

Am I going to pay too much for a metal roof or get real long-term value? If you worry about surprise bills, confusing quotes, or which metal will last, this guide clears the fog and shows exact numbers so you can plan with confidence.

Quick snapshot — what you need to know first

Metal Roof Cost varies mainly by material, roof size, and installation complexity. On average installed prices range roughly $4 to $30 per square foot, with most homeowners paying in the middle of that band depending on choices. Expect higher prices for premium metals (copper, zinc) and standing-seam systems.

How metal roof pricing works — basics explained

A roof quote breaks into clear parts:

- Materials — panels, shingles, fasteners, trim.

- Labor — cutting, fitting, sealing, flashing.

- Prep and disposal — old-roof tear-off, cleanup, dumpster.

- Underlayment and accessories — underlayment, vents, ice and water shield.

- Permits and inspections — local fees if required.

Contractors usually price by square foot or square (1 square = 100 sq ft). A typical estimate lists material cost per sq ft and labor cost per sq ft. Regional labor rates and local code needs change the final number.

Cost by material

Below is a practical table that shows typical installed cost per square foot by material type. These are ranges homeowners commonly see in 2025–2026 markets and include materials plus installation.

| Material | Typical installed cost / sq ft | Typical lifespan (years) | Notes |

|---|---|---|---|

| Corrugated Galvanized / Galvalume Steel | $7 – $12 | 25 – 40 | Budget friendly; exposed fasteners need periodic check. |

| Painted Steel (panels or shingles) | $6 – $21 | 30 – 50 | Common residential option; wide price range by gauge & finish. |

| Aluminum | $9 – $20 | 30 – 50 | Good for coastal areas (resists corrosion). |

| Standing-seam (steel or aluminum) | $10 – $30 | 40 – 70 | Interlocking panels, low leak risk, higher labor cost. |

| Zinc or Zinc-alloy | $12 – $30 | 50 – 100 | Long lasting, premium price, patinas over time. |

| Copper | $15 – $40+ | 50 – 100+ | Luxury finish, long life, highest material cost. |

These ranges overlap because:

- Panel profile and gauge affect price.

- Paint finish and coatings (e.g., PVDF) add cost.

- Complexity of roof increases labor, not material price alone.

Cost by roof size

Roof estimates scale with area, but not perfectly. Larger roofs get better per-sq-ft deals because fixed costs spread out. Below are installed cost examples by roof area using three common material tiers: low, mid, and premium.

| Roof area (sq ft) | Low tier avg cost ($/sq ft) | Mid tier avg cost ($/sq ft) | Premium avg cost ($/sq ft) | Total low | Total mid | Total premium |

|---|---|---|---|---|---|---|

| 1,000 | $8 | $14 | $24 | $8,000 | $14,000 | $24,000 |

| 1,500 | $7.75 | $13.50 | $22.50 | $11,625 | $20,250 | $33,750 |

| 2,000 | $7.50 | $13.00 | $21.00 | $15,000 | $26,000 | $42,000 |

| 3,000 | $7.00 | $12.00 | $20.00 | $21,000 | $36,000 | $60,000 |

How to read this: a 1,500 sq ft roof (about 15 squares) with a mid-tier standing seam or good-quality painted steel system commonly costs $20k–$21k installed. National surveys and contractor reports show similar mid-range totals.

Practical cost breakdown — exact line items

A typical installed metal roof quote splits into these line items. I list estimated shares so you can check a quote line by line.

- Materials (40–55%) — panels, trim, screws, underlayment. Premium metals push this share higher.

- Labor (30–40%) — experienced crews charge more; difficult roofs increase this.

- Removal & disposal (5–10%) — tear-off of old roof or cost to install over existing roof.

- Permits & inspections (1–3%) — varies by city.

- Accessories & flashings (3–8%) — ridge caps, valleys, gutters, vents.

Example: On a $20,000 installed roof, $9,000–$11,000 may cover materials while $6,000–$8,000 covers labor.

Why standing seam costs more

Standing-seam systems use long, interlocking panels and hidden fasteners. They require:

- Accurate panel rolling/ordering to length.

- Skilled installers for seams and seams folding.

- More trim and custom flashing at penetrations.

This drives labor and quality control costs up, but gives a longer lifespan and fewer leaks. For homeowners who plan to keep the house decades, standing seam often yields better value.

Energy and lifecycle savings — numbers that matter

Metal roofs can cut cooling costs because they reflect solar heat. Studies and industry data show cooling savings commonly range from 10% to 25%, depending on climate, roof color, and insulation. Some sources and case studies indicate larger savings in specific configurations. Over time, reduced energy bills plus avoided roof replacements can make metal cost-competitive with shingles. ORNL and industry research highlight meaningful savings and long life for coated metal systems.

Lifespan comparison (typical):

- Asphalt shingles: 15–30 years.

- Metal: 30–70+ years depending on material and maintenance.

Real examples — calculate your expected total

Use this simple method: measure your roof area in square feet (not just house footprint) or ask your roofer. Then multiply by a realistic installed price for your chosen material.

Example 1 — Simple 1,200 sq ft roof (low slope), painted steel:

- Area: 1,200 sq ft

- Price: $12 / sq ft (installed mid range)

- Total installed ≈ $14,400

Example 2 — 2,000 sq ft complex roof (lots of valleys), standing seam aluminum:

- Area: 2,000 sq ft

- Price: $18 / sq ft (higher due to complexity)

- Total installed ≈ $36,000

These examples match published national averages and contractor reporting. When you get quotes, verify whether the price is per square foot or per square.

Factors that push the price up — checklist to watch

- Steep pitch or many dormers.

- Multiple roof planes and valleys.

- Rooftop equipment or many penetrations (chimneys, skylights).

- Need for structural reinforcement or sheathing replacement.

- Regional labor shortages or high permit costs.

- Premium finishes (PVDF paint, Kynar) or thick gauges.

Ask your contractor to list these items on the estimate. If a competitor’s price is much lower, check whether they cut corners on underlayment, flashing, or warranty coverage.

Warranties and expected maintenance

- Manufacturer warranty: cover material defects, often 20–40 years for painted finishes.

- Workmanship warranty: offered by the contractor; often 1–10 years.

- Maintenance: metal roofs need visual checks for screws, sealant, and gutters; cleaning and repainting may be required after decades.

A strong warranty from a reputable manufacturer plus a qualified contractor reduces long-term risk and can be worth a higher upfront cost.

Choosing the right metal for your situation — short guide

- Budget and value: choose painted steel or corrugated steel for lowest price with good life.

- Coastal exposure: choose aluminum to resist salt corrosion.

- Longest life and luxury: copper or zinc, but expect steep upfront cost.

- Energy focus: choose a light, reflective finish and add proper insulation and ventilation.

Use real local examples—ask neighbors or roofer portfolios—so you see how the finish looks on houses near you.

How to get accurate quotes — a simple process

- Measure the roof or get a professional measurement. A measured plan avoids guesswork.

- Ask for itemized estimates (materials, labor, tear-off, permit, accessories).

- Compare apples to apples — same underlayment, same warranties, same removal option.

- Verify license and insurance — request copies before work starts.

- Check references and past jobs — see completed roofs, not just photos.

- Get a written contract with timeline, payment schedule, and warranty language.

Follow these steps and you will avoid surprise add-ons.

Financing and cost-saving strategies

- Energy tax credits or rebates: some local utilities offer rebates for cool roofs or energy upgrades. Check local programs.

- Install over existing shingles: allowed in some places; saves tear-off cost but watch local code and warranty rules.

- Phased upgrades: replace only the most damaged sections first if budget is tight (but this may reduce warranty coverage).

Confirm rebates and rules with your local utility or building department before assuming savings.

Long-term value: is metal worth it?

When you compare long lives (30–70+ years) and lower maintenance for metal against asphalt’s 15–25 years, the lifecycle cost often favors metal over 30–50 years. Factor in:

- Fewer replacements.

- Lower insurance premiums in some areas for fire or hail resistance.

- Energy savings in warm climates.

- Higher resale value and curb appeal.

These combined effects explain why many homeowners accept a higher initial cost for metal.

Common contractor pricing traps to avoid

- Too low to be true: may reflect omitted items like flashing or ice shield.

- Vague warranty: check who pays for labor if a leak happens later.

- Unclear permit handling: you want the contractor to pull permits unless you accept risk.

- Cash discounts with no paperwork: avoid—get everything in writing.

Ask to see the exact materials brand and gauge listed in the contract.

Maintenance checklist

- Inspect gutters and flashings twice a year.

- Clear debris and overhanging branches regularly.

- Tighten or replace exposed fasteners as needed.

- Keep touch-up paint for scratches to avoid corrosion.

Routine checks prevent small problems from becoming expensive repairs.

Case study — sample budget and savings

Home: 1,800 sq ft roof area, hot climate, mid-sized two-story house. Options compared:

- Asphalt shingles: $4.50 / sq ft installed → $8,100 total. Lifespan 20 years.

- Painted steel: $13.00 / sq ft installed → $23,400 total. Lifespan 35–50 years. Energy savings estimate 12% on cooling.

- Standing seam aluminum: $19.00 / sq ft installed → $34,200 total. Lifespan 40–60 years. Energy savings estimate 15–20%.

If cooling costs were $2,400/year, a 12% saving = $288/year. Over 25 years, that equals $7,200 (ignoring escalation). When combined with avoided shingle replacements, the metal options close the gap on lifecycle cost. Use local energy prices for a more precise calculation.

People Also Ask

Final checklist before you sign a contract

- Get three itemized quotes.

- Confirm material brand, gauge, and finish in writing.

- Verify contractor license and insurance.

- Ask for workmanship and material warranties in writing.

- Confirm start and finish dates and payment milestones.

Conclusion

A metal roof costs more up front than asphalt, but it pays back through long life, lower maintenance, and energy savings. Decide first on material (steel, aluminum, standing seam, copper) and get itemized quotes. Compare line items and warranties, not just the bottom line.

For local expertise, accurate measurements, and professional quotes tailored to your home, visit Akron Roofing Experts for details and to request a free estimate: akronroofingexperts.com