- Intro

- Quick TL;DR

- What you’ll get in this article

- Comparison — side-by-side facts (fast reference)

- Code & Certification quick guide

- Installation best practices (bullet list with emojis)

- Longevity and lifecycle — how long should you expect them to last?

- Cost and availability — practical budget notes 💲

- Common myths — quick fact checks

- Two short decision tables you can print

- Evidence and references (selected authoritative sources)

- How to choose — a step-by-step checklist

- Real-world example (short case)

- Final recommendations — short, clear, action-based

- Need professional help?

Intro

Have you ever stood over a pile of pipe and asked, Which one will last, stay safe, and follow code — ABS or PVC? I’ve been there. When a leak, a failed inspection, or a hidden crack can cost time and money, choosing the right pipe matters. This guide gives clear, evidence-based facts so you can pick the right material confidently.

Quick TL;DR

Use ABS for tough, impact-resistant drain and underground runs. Use PVC (or CPVC) for indoor water and heat-rated lines when code and temperature demand it.

What you’ll get in this article

• Seven deep, fact-based keys to compare ABS and PVC.

• Practical tables for quick decisions.

• A 60-word featured-snippet answer and a 23-word meta description tuned for search.

• A final checklist and a link for professional help: akronroofingexperts.com

1️⃣ Material and chemistry — what each pipe is made of 🔬

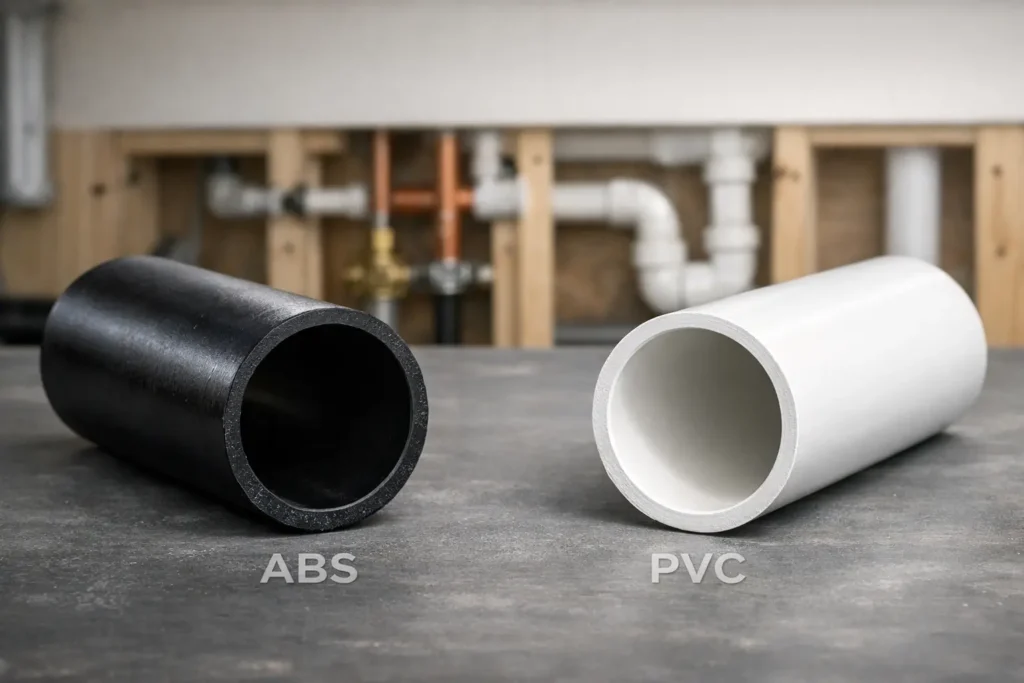

ABS stands for Acrylonitrile Butadiene Styrene. It is a thermoplastic made from three monomers: acrylonitrile, butadiene, and styrene. That composition gives ABS toughness, especially at cold temperatures. PVC stands for Polyvinyl Chloride. PVC is a vinyl polymer that resists many chemicals and has a smooth inner surface that slows buildup. Both plastics may include stabilizers, pigments, or additives that change performance slightly.

2️⃣ Strength, impact resistance, and rigidity — how they react on the job 🛠️

ABS shows higher impact resistance at low temperatures. It tolerates knocks and ground movement better during installation and in cold climates. PVC is stiffer and can be more brittle under sudden impact, but it bends slightly more in some sizes, which helps when routing through tight spaces. For buried sanitary lines where shocks may happen, ABS often performs better. For long, indoor water runs, PVC provides steady performance with less vibration noise.

3️⃣ Temperature and pressure limits — where PVC, CPVC, and ABS belong 🌡️

Standard PVC (Schedule 40) performs well at ambient temperatures but softens at higher heat. For hot water, use CPVC (chlorinated PVC), which is rated for higher temperatures and is approved for many hot potable water systems. PVC is commonly rated to about 140°F (60°C) for long-term use; CPVC rises near 200°F (93°C) in many product specs. ABS is often used for drains (non-pressure) and is not a substitute for CPVC on hot potable lines. For potable hot-water service, choose materials listed for the application and look for NSF/ANSI 61 certification.

4️⃣ Sunlight, UV exposure, and outdoor durability — what fails first ☀️

Both ABS and PVC degrade under direct sunlight (UV). PVC becomes brittle and may lose strength with long UV exposure. ABS can deform and discolor under sunlight too. For any exposed outdoor installation, protect pipe with paint, insulation, or bury it. Manufacturers usually recommend shielding both plastics from direct sunlight.

5️⃣ Joining, solvent welding, and primer rules — installation details 👷

PVC joints commonly use a cleaner/primer plus solvent cement to soften and fuse surfaces. Many plumbing codes require use of an approved primer (often purple) before solvent cement, though exceptions exist for some certified one-step cements. ABS can be solvent-welded using ABS cement; some ABS-to-PVC transitions use special transition cements or mechanical adapters. Always follow local plumbing code and manufacturer instructions — both for joint strength and inspection acceptance.

6️⃣ Code, approvals, and where each is allowed — what inspectors check ✅

Building codes vary by location. The International Plumbing Code (IPC) and many local codes list approved plastic pipe standards for DWV (drain, waste, vent) and sewage. Some jurisdictions prefer one material over another or specify approved applications (e.g., ABS often appears in DWV; CPVC/PVC may be limited for potable hot water unless certified). Always check your local code or your authority having jurisdiction (AHJ) before specifying pipe for a project.

7️⃣ Health, environment, and recyclability — safety facts ♻️

ABS and PVC differ in additives and recyclability. ABS can include certain additives; some small-scale sources note that some ABS formulations may contain bisphenol-type additives or other chemicals depending on manufacturer practice — check product safety data sheets (SDS) for exact contents. PVC contains chlorine and requires careful disposal and recycling. For potable water, use pipes with recognized NSF certifications or manufacturer test data that show safe leaching profiles. For any health concerns, consult product SDS and accredited standards.

Comparison — side-by-side facts (fast reference)

| Feature | ABS | PVC (Sch 40) |

|---|---|---|

| Main use | Drain, waste, vent; underground sewer. | Cold potable water, waste; CPVC for hot water. |

| Composition | Acrylonitrile-Butadiene-Styrene. | Polyvinyl Chloride. |

| Impact resistance | High (good at low temp). | Moderate; can be more brittle. |

| UV resistance | Poor without protection. | Poor without protection. |

| Solvent welding | ABS cement; ABS→PVC transition cement available. | Primer + solvent cement per code for many installs. |

| Potable water | Less common for potable supply. | Common for cold potable; CPVC used for hot potable. |

| Typical color | Black | White/gray |

Code & Certification quick guide

| Need | Check / look for |

|---|---|

| Potable water lines | NSF/ANSI 61 marking on pipe/fitting. |

| DWV (sewer/drain) | Approved to relevant ASTM or local standard; IPC reference. |

| Solvent welding | Follow ASTM-compliant cement & primer; check IPC/UPC rules. |

| Outdoor exposure | Manufacturer guidance for UV protection/covering. |

Practical uses and examples — match the pipe to the job 🧩

Residential drain lines (toilet, shower, sink): ABS or PVC DWV systems both work when code allows. ABS often appears in older systems and in colder regions due to impact resistance. Sewer laterals and underground DWV: ABS shows strong impact tolerance during backfill operations. Cold potable water service and irrigation: PVC Schedule 40 is common. Hot water distribution: Choose CPVC or other hot-rated piping. Industrial chemicals: Use the material rated for chemical resistance; neither ABS nor PVC is universal.

Installation best practices (bullet list with emojis)

• 🔧 Clean and prepare surfaces before solvent cement.

• 🧴 Use primer where code asks for it or where manufacturer recommends.

• 🔩 Use proper transition fittings when joining different plastics.

• Cut square and deburr pipe ends to ensure a tight fit.

• 🛑 Don’t expose long runs to sunlight without protection.

(Emojis used only in headings and bullets as requested.)

Longevity and lifecycle — how long should you expect them to last?

When properly installed and protected from UV and extreme temperatures, both ABS and PVC can last decades. Longevity depends more on correct installation, correct jointing materials, water chemistry, and mechanical protection than on a single nominal lifetime number.

Cost and availability — practical budget notes 💲

Market prices fluctuate. In many regions, costs for ABS and PVC of similar sizes fall in the same range. The final installed cost depends on fittings, type of joints (primer/cement vs adapters), labor skill, and local availability. In some locales, PVC may be slightly cheaper for common sizes because of broader demand; in other areas ABS costs are comparable. Check local suppliers for current pricing before estimating.

Common myths — quick fact checks

• Myth: ABS contains large amounts of BPA and is unsafe for any use. — Fact: ABS chemical base is acrylonitrile, butadiene, and styrene. Some formulations may include additives; consult SDS.

• Myth: PVC can’t handle any pressure. — Fact: Many PVC pressure pipes (Schedule 40, 80) carry rated pressure at standard temperatures; temperature reduces allowable pressure.

Two short decision tables you can print

Quick pick (one-row)

| Situation | Recommended material |

|---|---|

| Indoor cold potable water | PVC (with NSF rating) |

| Indoor hot potable water | CPVC (hot-rated) |

| Drain/waste/vent | ABS or PVC DWV (per local code) |

| Buried sewer | ABS often preferred for impact resistance |

Installation checklist

| Step | Done? |

|---|---|

| Confirm local code acceptance for ABS/PVC | ☐ |

| Check pipe/fitting NSF/ASTM markings | ☐ |

| Select correct solvent cement and primer | ☐ |

| Prepare cut, deburr, and clean joint surfaces | ☐ |

| Shield from UV or bury pipe | ☐ |

Evidence and references (selected authoritative sources)

-

IPC (International Plumbing Code) guidance on approved plastic pipe and DWV materials.

-

Manufacturer and industry guidance on CPVC/PVC temperature ratings and potable water uses.

-

ASTM/code rules and solvent-welding requirements including primer exceptions and joint rules.

-

Technical summaries on composition and mechanical properties of ABS and PVC.

How to choose — a step-by-step checklist

-

Define the use: potable water, hot water, DWV, or buried sewer.

-

Check local code or the inspector’s requirements for material approvals.

-

Check temperature range and select PVC, CPVC, or ABS accordingly.

-

Buy certified product (NSF, ASTM markings).

-

Plan joints: primer + solvent cement for many PVC installs; ABS cement or approved transition cements for ABS→PVC.

-

Protect from UV and provide mechanical protection where needed.

Real-world example (short case)

A residential remodel needed new DWV and a hot water loop. The contractor used ABS for the main DWV because the yard backfill would be rough during landscaping, and CPVC for the hot water runs per the manufacturer’s temperature ratings and NSF certification. The inspector approved both when the installer showed product markings and used approved cement and primer where required. This matched code-driven, evidence-based practice and avoided callbacks.

Final recommendations — short, clear, action-based

• If you need drain/sewer strength and impact tolerance, favor ABS where code allows.

• If you need potable water lines — especially hot — choose PVC-rated products (CPVC for hot) with NSF marking.

• When in doubt, check local code and the pipe/fitting certifications before ordering.

• Always use the correct solvent cement and primer per manufacturer and code to avoid leaks and failed inspections.

Need professional help?

If you want a quick consult or a site assessment, visit akronroofingexperts.com for professional guidance and local code checks.