Is your commercial property’s roof showing signs of wear? Choosing the right roofing system can be overwhelming. There are many materials and options to consider. Factors like durability, energy efficiency, budget, and building design are key. So, where do you start?

At Akronroofingexperts, we know this decision can be tough. With over 30 years in commercial roofing, our team has helped many property owners. Whether you need a new roof or a quick repair for a leak, we’re here to support you. Our goal is to give you the knowledge you need to make a confident choice. Let us help you protect your investment with a roofing solution that fits your building perfectly.

When it comes to selecting the right commercial roofing system, the first step is a thorough roof inspection. While we can’t physically inspect your roof today, we can certainly share the knowledge we’ve gained from nearly 30 years of hands-on commercial roofing experience.

In this article, we’ll walk you through everything you need to know to get started:

- The various types of commercial roofs available

- Four key factors to consider when choosing the best roofing system for your property

- The top five commercial roofing systems on the market

- The pros and cons of each option

By the time you’re done reading, you’ll have a clearer understanding of your commercial roofing options—along with the benefits and drawbacks of each. Our goal is to help you feel confident and informed as you plan your next commercial roof investment.

Let’s dive in!

Understanding Commercial Roofing Options

3 Main Types of Commercial Roofing Construction

When it comes to commercial buildings, roofing systems generally fall into one of three categories:

- Flat Roof Construction

- Low Slope Roof Construction

- Steep Slope Roof Construction

1. Commercial Flat Roof Construction

Flat roofs are a popular choice in commercial construction because they give architects and engineers more flexibility—especially when space is limited. These roofs make it easy to install rooftop equipment such as HVAC units or solar panels.

However, modern flat roofs aren’t truly flat—they’re built with a slight slope using tapered insulation. This allows for proper drainage, helping to avoid standing water that can cause damage over time. Tapered insulation also enhances the building’s R-value, improving energy efficiency. While this improves performance, it does add to the overall project cost.

2. Low Slope Roof Construction

Low slope roofs have just enough angle to direct water off the roof but are flatter than steep-slope designs. While they support good water drainage, not all roofing materials perform well on low slopes.

For instance, installing metal on a low slope roof can lead to leaks and maintenance issues. TPO roofing is often a better fit, offering durability and watertight protection specifically suited to low slope applications.

3. Steep Slope Roof Construction

Steep slope commercial roofs look a lot like residential roofs. Common styles are gable roofs and hip roofs. They are usually built with metal or wood trusses or custom-framed with 2x wood.

These roofs often use high-performance materials like standing seam metal roofing. This material is durable, weather-resistant, and lasts a long time. It’s a popular choice for condos, office buildings, and retail properties.

Each roof type has its own cost, maintenance, and functionality factors. So, understanding these differences is key to choosing the right system for your building.

Key Factors to Determine the Best Commercial Roof

Choosing the right roofing system for your commercial building involves more than just picking a material. You must consider several key factors that affect performance, longevity, and value. Here are four important points to keep in mind:

1. Building Structure and Design

The design and layout of your building are crucial. Flat or low-slope buildings often work well with membrane roofing, like TPO or EPDM. In contrast, steep-slope roofs may be better suited for metal or shingle systems.

2. Climate and Weather Conditions

Your local climate matters. Areas with heavy rain, snow, or strong sun need roofing materials that can withstand these conditions. Consider UV resistance, waterproofing, and insulation based on your region.

3. Budget and Life Cycle Costs

Upfront costs are important, but long-term expenses also matter. Maintenance, repairs, and energy efficiency can add up. Some roofing systems might be pricier initially but offer lower lifetime costs due to their durability and reduced upkeep.

4. Usage of the Roof Space

How you plan to use the roof affects your choice. If heavy equipment or foot traffic is expected, select a system designed for durability and load-bearing strength.

Considering these factors will help you choose a roofing solution that fits your building’s needs now and in the future.

Top 5 Commercial Roof Types

- Single-ply roofing (TPO, PVC & EPDM roofing)

- Modified Bitumen (rubber roofing)

- Built-up roof (hot tar roofing)

- Metal Roofing (standing seam & screw down)

- Asphalt shingles (upgraded shingles)

1. Single-Ply Roofing: TPO, PVC & EPDM

Single-ply roofing systems are popular for flat roofs on both commercial and residential buildings. These membranes come in various thicknesses, often called 45 mil or 60 mil. “Mil” means thousandths of an inch, so a higher number indicates a thicker, more durable membrane.

Thicker membranes usually provide longer manufacturer warranties. They also resist wear, weather, and UV exposure better.

You can choose from TPO, PVC, or EPDM. Each type offers great waterproofing, flexibility, and energy efficiency. They work well for flat or low-slope roofs.

Estimated Cost: Ranges from $10.50 to $15.50 per square foot, based on the material type, thickness, and installation complexity.

2. Modified Bitumen Roofing: Benefits and Drawbacks

Modified bitumen (Mod-bit) roofing is seen as the second generation of commercial flat roofing. It follows traditional built-up (hot tar) systems. Built-up roofs needed risky and labor-intensive setups. These included hot tar kettles heated to over 500°F. In contrast, Mod-bit roofs provide a safer and more flexible option.

Today, most contractors install modified bitumen without using hot tar. Instead, these roofs can be applied using several safer and more efficient methods:

-

Hot tar applied

-

Cold adhesive applied

-

Torch applied

-

Self-adhered (peel-and-stick)

The self-adhered method has become especially popular due to its speed, safety, and ease of installation.

Benefits:

-

Multi-layered system enhances durability.

-

Better suited for commercial roofs with high foot traffic.

-

Provides strong waterproofing and weather resistance.

Drawbacks:

-

Higher installation and material costs due to multiple layers.

-

Repairs and maintenance can be more complex and expensive.

Estimated Cost: Between $6.50 and $11.50 per square foot.

3. Built-Up Roofing (BUR): Hot Tar Roofing Explained

Built-up roofing (BUR) gets its name from layering materials. This method creates a strong, multi-ply system. To install it, workers stack layers of fiberglass roofing rolls with hot tar. This forms a “built-up” structure. BUR has been the standard for flat roofing for many years.

Installation Process:

The core of a BUR system involves heating asphalt (tar) to temperatures of 450 to 500 degrees and then mopping it onto the roof deck or insulation—similar to mopping a floor. Between each application of hot asphalt, layers of fiberglass or felt roofing material are rolled out. Most BUR systems use four to six layers, depending on the desired durability.

The top layer is crucial for the roof’s longevity and ease of maintenance. Often, it’s sealed with a flood coat of hot asphalt and rocks or gravel. While this layer provides solid protection, repairs can be difficult, especially when it has a rock finish. However, if the top layer has an asphalt flood coat or granule cap sheet, it becomes easier to maintain.

Advantages:

-

Durability: Built-up roofs can last 20-30 years, making them a long-lasting investment.

-

Foot Traffic Resistance: The multiple layers make BUR systems ideal for roofs exposed to heavy foot traffic.

Disadvantages:

-

Cost: Due to the multiple layers, BUR installations are costly, often requiring substantial labor and materials. For example, a 10,000-square-foot building would require at least 30,000 square feet of roofing to ensure proper coverage.

-

Installation Complexity: Heating asphalt to extreme temperatures and applying it on the roof is a dangerous and labor-intensive process.

-

Maintenance: While repairs can be done, they are challenging and require experienced roofers, particularly with a gravel finish.

Estimated Cost: Between $15.50 and $25.50 per square foot, depending on the layers and specific materials used.

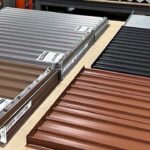

4. Metal Roofing: Standing Seam & Screw-Down

Metal roofing is a favored option for commercial properties due to its curb appeal, durability, and long lifespan. There are two primary types of metal roof systems commonly used:

-

Standing Seam Metal Roofing

-

Screw-Down Metal Roofing

Standing Seam Metal Roofing is a concealed fastener system, meaning the fasteners are hidden beneath the panels. In contrast, Screw-Down Metal Roofing features exposed fasteners, which are visible through the metal panels. Both systems offer unique advantages and drawbacks.

Advantages of Standing Seam Metal Roofing:

-

Longevity: A well-installed standing seam roof can last over 50 years.

-

Wind Resistance: It has a high wind rating and won’t blow off in storms.

-

Aesthetic Appeal: Standing seam roofs add significant value and a modern look to any building.

-

Durability: These roofs are built to withstand the elements and require minimal maintenance.

Disadvantages of Standing Seam Metal Roofing:

-

Cost: Standing seam roofs are more expensive due to the time-consuming installation process and the expertise required for flashing installation.

Advantages of Screw-Down Metal Roofing:

-

Affordability: This system is more budget-friendly than standing seam roofs.

-

Curb Appeal: Screw-down metal roofs still offer an attractive appearance.

Disadvantages of Screw-Down Metal Roofing:

-

Maintenance: Screw-down roofs often require maintenance within the first 5 years, as the exposed screws can loosen due to thermal movement (expansion and contraction).

There are three primary materials used in metal roofing systems across the U.S., all known for their durability and cost-effectiveness:

-

Aluminum

-

Steel

-

Galvalume

These materials are available in various profiles, including standing seam, screw-down, and shingle-style, providing a broad range of aesthetic options and price points suitable for different commercial needs.

Aluminum Metal Roofing

Aluminum is one of the most energy-efficient metal roofing materials available today. It comes in various thicknesses, with the most commonly used being .032, .040, and .050. The higher the number, the thicker the aluminum roofing will be. For commercial roofs, the .032 and .040 thicknesses are the most popular choices.

Aluminum roofing is available in two finishes:

-

Mill Finish: This provides a raw, natural metal look, and over time, the material oxidizes into a beautiful, weathered finish.

-

Painted Finish: Aluminum also comes in a wide range of colors, and painted finishes often come with warranties ranging from 40 to 45 years, providing long-lasting protection against fading and weathering.

The cost of an aluminum roof system typically ranges from $15.50 to $18.50 per square foot, making it a durable yet cost-effective option for commercial roofing.

Steel Metal Roofing

Steel roofing is the most popular metal material for commercial buildings. It is affordable and effective. Steel is usually galvanized, coated with zinc to stop corrosion. This makes it a durable and reliable option.

Steel roofing comes in several gauges. The most common are 24, 26, and 29 gauge. Unlike aluminum, a lower gauge number means thicker steel.

Here are some popular steel roofing profiles for commercial properties:

-

Standing Seam Metal Panels: 12”-18” wide panels with hidden fasteners.

-

Interlocking Steel Shingles: Look like slate or shake, with hidden fasteners.

-

5-V Crimp Metal Roofing: 2-foot wide panels with exposed fasteners.

-

R-Panels or Multi-Rib Panels: 3-foot wide panels with exposed fasteners.

Steel needs a protective painted finish since it isn’t naturally corrosion-resistant. Paint warranties usually last from 20 to 45 years. This depends on the metal’s thickness, panel type, and manufacturer.

Steel roofing is a cost-effective choice, with prices between $10.50 and $15.50 per square foot. It offers a variety of styles, thicknesses, and warranties to meet different commercial needs.

Galvalume Metal Roofing

Galvalume metal roofing consists of a steel core coated with aluminum. This coating improves corrosion resistance, much like steel roofing. It comes in 24 gauge, 26 gauge, and 29 gauge thicknesses. You can find it in all four common roofing panel profiles.

A key difference with Galvalume is its mill finish rather than a painted finish. This makes it more affordable than painted metal options. Also, Galvalume is easier to handle during installation. It is less likely to scratch compared to painted materials.

Galvalume roofing works well in saltwater areas. The aluminum coating helps prevent corrosion from salty air.

The cost of a Galvalume roof system usually ranges from $8.50 to $13.50 per square foot. This makes it a budget-friendly and durable choice for commercial buildings.

5. Asphalt Shingles for Commercial Buildings

Asphalt shingles are often thought of for homes, but they are also common on commercial buildings. The shingles used in commercial settings are usually upgraded or designer shingles. These differ from the standard builder-grade shingles found in new homes.

Builder-grade shingles have limited wind protection and typically need replacing every 10 to 12 years. In contrast, designer shingles offer better wind resistance, improved curb appeal, and a lifespan of 25 to 35 years. This makes them a favored option for commercial properties.

However, one downside is that shingles may have a shorter lifespan than other commercial roofing materials. When it’s time to replace them, the process can disrupt business operations, especially for tenants or customers.

The cost for upgraded or designer asphalt shingles usually ranges from $5.50 to $8.50 per square foot. This makes them a cost-effective choice that enhances both performance and appearance.

Choosing the Right Commercial Roof for Your Building

When replacing a roof or planning new construction, consider these factors for your commercial building:

-

Foot Traffic: Will the roof handle heavy foot traffic?

-

Energy Efficiency: Does the roof need to boost energy efficiency?

-

Exposure to Grease or Chemicals: Is your roof near industrial elements like grease or chemicals?

-

Exposure to High Winds: Will high winds affect the roof?

-

Sun Exposure: How much sun will the roof get, impacting its durability?

-

Roof Visibility: Is the roof visible to customers or tenants, needing a nicer look?

-

Budget: What is your roofing project budget?

-

Longevity: How long do you want the roof to last before repairs or replacement?

The building’s use and the local climate are key in choosing the right roofing system.

We want you to feel confident in your choice. If you have questions or need expert advice on your commercial roofing project, our Akronroofingexperts commercial estimators can help. Click the Schedule an Inspection button to start!

Explore more insights in our Learning Center for additional resources on commercial roofing.